Titanium powder,"TILOP" (Gas atomized process)

Applications

Additive Manufacturing(AM), Metal Injection Molding(MIM), Spraying, Sputtering Targets, Hot Isostatic Press(HIP)

Gas Atomized Titanium Powder for Additive Manufacturing and Metal Injection Molding Applications

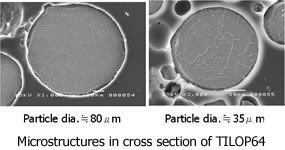

OTC has been producing gas atomized titanium powder since 1990. Our unique atomizing process does not require a crucible that might be a source of inclusions. Since OTC is known as one of the world largest titanium sponge producers, we are able to source aerospace quality titanium for producing the titanium powder. Due to OTC's unique atomizing process and the high quality titanium, we are proud to be able to provide our gas-atomized spherical titanium powder "TILOP (Titanium Low Oxygen Powder)" to our customers in the aerospace and medical industries.

Additive manufacturing technology has recently been the subject of considerable attention. It is believed that this technology can totally change the manufacturing process making it much faster, result in higher yields and have an overall benefit in terms of total production cost. Among a range of materials, titanium is said to be one of the most suitable materials to which additive manufacturing technology should be applied. Due to its high quality and spherical nature, TILOP is eminently suited to this promising field of additive manufacturing.

Even though additive manufacturing has become the focus of increased attention, another powder metallurgy process is also in the spotlight again, metal injection molding. This technology has a longer history than that of additive manufacturing. Since TILOP was developed especially for metal injection molding applications, our development of atomization technology has focused on the production of very fine powders. OTC's TILOP is also suitable for metal injection molding where extremely fine powder particles arerequired.

The spherical nature of TILOP also has advantages when it comes to hot isostatic press (HIP) applications. For example, several types of target plates used in the electronics device production process are manufactured by HIP using our titanium powder gas-atomized spherical.

OTC produces several titanium powders under the TILOP brand name These include commercial pure (CP) titanium powder, Ti-6Al-4V pre-alloyed powder (or Ti64 pre-alloyed powder), both with ranges of powder particle size distribution tailored to the customer's specific applications such as additive manufacturing and metal injection molding.

Gas-atomized titanium Powder (Ti-6Al-4V) Standard Grade for Additive Manufacturing

| Grade | Particle Size |

% | % max. | |||||||

| Ti | Al | V | Fe | O | C | N | H | Y | ||

| TILOP64-15〜45 AM TILOP64-105 AM |

15〜45μm 45〜105μm |

Bal. | 5.5 〜6.75 |

3.5 〜4.5 |

0.25 | 0.13 | 0.08 | 0.05 | 0.012 | 0.005 |

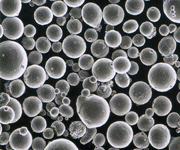

Photograph of appearance

TILOP (Gas-atomized titanium powder)

TILOP 100x magnification