-45μm

20 ~ 70mm

Granules

In 1961, we became the first in Japan to successfully manufacture silicon monoxide (SiO).

Since then, in close link with SiO users, we have been keeping efforts to improve quality and to reduce

prices.

Membranes which are vapor-deposited with silicon monoxide (SiO) exhibit excellent barrier properties

preventing the permeation of water vapor and oxygen. It is on this basis that SiO is used for making gas

barrier packaging films. Our high-quality SiO already has a proven track record as a barrier material for food

packaging and commands the largest share of the industry market. The range of uses of SiO is also expanding to

other business area than packing. The range of uses of SiO is expanding, such as in solar cell back sheets,

where even greater barrier properties are required, and as industrial packaging.

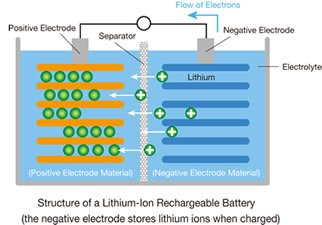

Dramatic growth is also expected in its use in negative electrodes of lithium-ion rechargeable

batteries, which have high levels of energy density and are widely used as power sources for mobile phones and

laptop computers. The advancing functionality of these devices demands higher battery capacity, which in turn

requires development of a next-generation negative electrode material with a greater electricity storage

capacity than those of conventional materials. We have positioned SiO as the most important material for

next-generation negative electrode materials. In order to commercialize SiO, we are undergoing assessments by

our customers (battery manufacturers) and conducting research and development.

The most outstanding feature of our silicon monoxide is its high purity. Semiconductor silicon grade high purity silicon is used as the raw material, and the vacuum technology from titanium sponge manufacture is leveraged to ensure a reliable supply of high quality products that other manufacturers cannot come close to matching.

SiO (Barrier Film)